PRODUCT

Eco-friendly Energy Material for Electrolysis

A core component material for polymer electrolyte membrane (PEM) electrolysis

- Titanium Porous Transport Layer (PTL)

- PEMEC Anode Porous Transport Layer

In polymer electrolyte membrane electrolysis cells (PEMEC), the porous transport layer (PTL) is a core component that determines hydrogen production efficiency and system durability.

In addition to its primary function of water transport, the PTL performs a number of functions to achieve electrical conductivity and structural stability.

- Product Features

- Optimized porous design engineered for excellent water management

- Excellent corrosion resistance

- Consistent pore structure

- Excellent mechanical rigidity

- Surface light control for an increased area of membrane contact

- Manufacturing Process

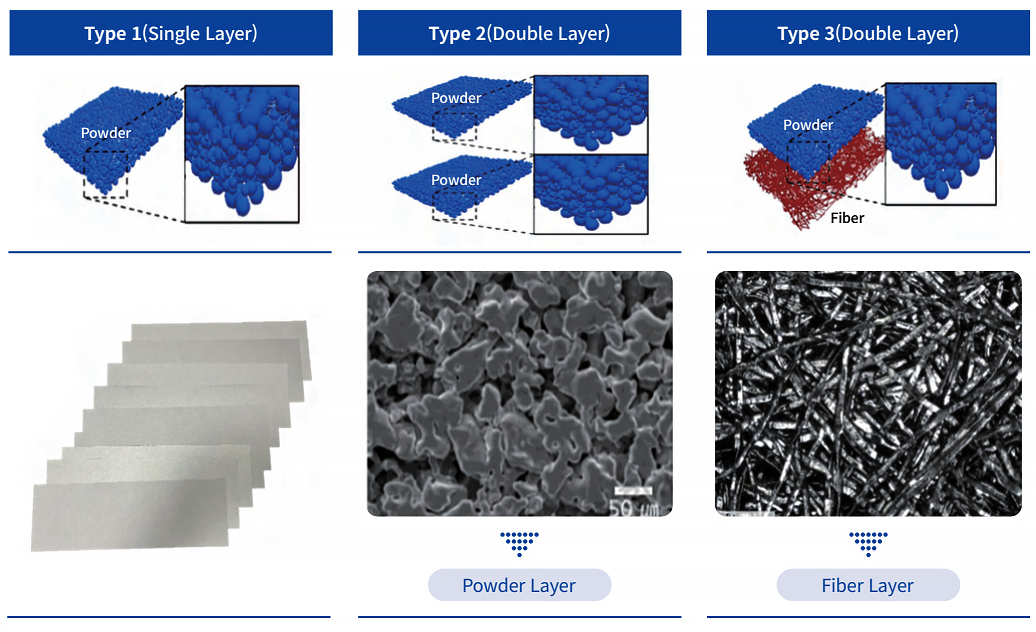

- Sintering technology is used to heat metal powders to a temperature below their melting point to combine their particles to achieve a strong porous structure.

Materials mixing

Casting

Debinding

Sintering

Pt Coating

Trimming

※ All processes completed in-house

- Competitiveness

- Domestically sourced titanium and ultra-precision processing technology are the key strengths behind Shinsung C&T's porous transport layer (PTL).

| Technical Competitiveness | Industrial Competitiveness | ||

|---|---|---|---|

| Titanium processing technology | Uniformity of porosity | Positioning in the value chain | Market growth |

| Shinsung C&T’s experience with display materials and processing technology is carried over into the precision processing, sintering, and surface finishing of PTLs. | In-house manufacturing and analysis facilities enable the sintering technology to achieve optimal porous structures of high density and low resistance. | A core component of the PEM electrolysis cell, suppliers of PTLs are limited because of barriers in production cost and technology. | With the electrolytic cell as a core technology for today’s mass production of green hydrogen, the market for PTLs is growing fast. |

- PTL Technical Data

| Typical Properties | Unit | Value | Remark |

|---|---|---|---|

| Thickness | ㎛ | 160, 260, etc | ASTM D 3652 |

| porosity | % | 40 | Shinsungcnt method |

| Surface roughness | ㎛ | Sa 3.0 | Shinsungcnt method |

※ Customization possible according to customer’s requirements.e

- Surface

| Surface | High Profile | Contact Area |

|---|---|---|

| 40x magnification | Red : High, Blue : Low | Red : Contact, Gray : Non-Contact |

※ Contact Area : Potential Consideration of membrane expansion

In a PEM (polymer electrolyte membrane) water electrolysis cell, the electrolyte membrane

expands as it absorbs water during operation.

- Performance and Durability

I-V Curve

Durability

- Test Condition

- Size = 25㎠

- Temp.=65℃

- Membrane=Nafion 115(127㎛)

- Anode= PTL (IrO2)

- Cathode = GDL(Pt/C)

- Vision and Roadmap

Growth into a global hydrogen technology leader

- Development of new technology that creates high added value and satisfies market needs

- Establishment of a mass production system to meet growing hydrogen commerce demands

- Pioneering of new global markets

Stage 1

2021-2023

- Base technology

- development R&D

Stage 2

2023-2025

- Investment in and validation of mass production lines

Stage 3

2026-

- Investment in mass production facilities

- Next-generation PTL development

Stage 4

2030-

- Establishment of additional production bases

- Increases in supply